The words of a customer: Willem Koster (COO Vitals)

‘De Budelse has lived up to high expectations as an innovative and sustainable printer’

Vitals ambition is to develop the most progressive food supplements. The quality and scientific substantiation of the ingredients are central to this. This ambition also includes a conscious choice for sustainability. “As a company, we are a strong supporter of the circular economy,” says Willem Koster, COO of Vitals. “That is why we opt for optimally recyclable packaging, and we strive for a lower CO2 footprint. That’s how we came to De Budelse, who now prints our bilingual packaging on Paperwise cardboard.”

Vitals never stands still. The company is continuously expanding its range, improving products and entering new markets. For example, we wished to further market our food supplements in Germany, Austria and Switzerland. “We seized the opportunity of these expansion plans to make a step towards sustainability,” Willem Koster continues.

Biobased containers and boxes from agricultural waste

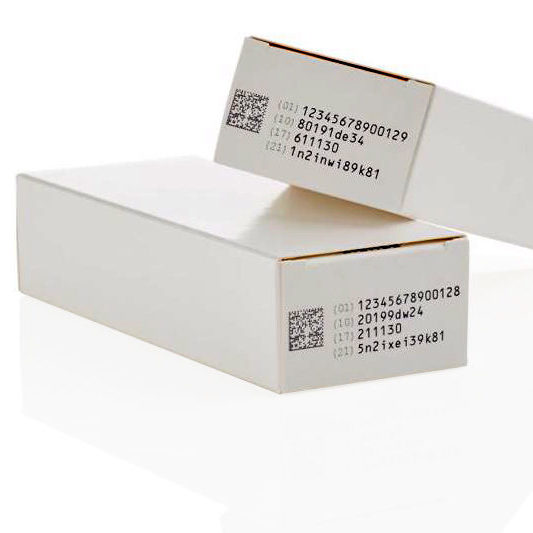

When choosing packaging, Vitals faced an important consideration: what is the most sustainable solution? “We opted for new, recyclable, biobased plastic containers,” Willem Koster explains. “They are packaged in boxes made of PaperWise cardboard. It is a CO2-neutral product made from plant residues left over after harvesting. Using agricultural waste as a raw material for paper and cardboard is environmentally friendly, and it gives farmers an extra source of income.”

we opt for optimally recyclable packaging and we strive for a lower CO2 footprint

Expectations fulfilled

Vitals inquired at PaperWise which printer was suitable for printing this sustainable cardboard packaging. A referral brought the company into contact with De Budelse. Willem Koster is very pleased with the collaboration. “De Budelse already had experience with PaperWise cardboard and seemed to have advanced collaboration possibilities. That was the deciding factor for us in choosing them. And let’s be honest: De Budelse has more than lived up to the high expectations as an innovative and sustainable printer. Not only do they print the boxes in two languages, but they also arrange for the printing of the associated labels. And they took us on board from the very first design. It is really great for Vitals to have a single point of contact for all printed matter.”

Self-sufficiency

Willem Koster notices that the collaboration with De Budelse has made further progress in the possibilities of managing files, ordering, storing and delivering printed matter. “In the long run, we will certainly make use of these opportunities,” he reflects on the future. “We would like to be more self-sufficient. For example, it works much more effectively if we adjust the designs, prepare them for production and place the orders via the automated system, without intervention from third parties. Once we have control by ourselves, it will be child’s play to make small adjustments and place orders.”

Ambition

Vitals is pleased that De Budelse also attaches great importance to the unique combination of ambition and sustainability. “We are not a marketing company that sells hot air,” concludes Willem Koster. “Ambition is our starting point. We want to develop progressive food supplements that meet a need. The information we provide is crucial. A product will not be included in our range without a solid scientific basis. In addition, we want to take care of people’s health and the health of our planet. It’s great that those values are also shared by De Budelse.”